Special Purpose Machine

SPECIAL PURPOSE MACHINE MANUFACTURER AND SUPPLIER IN INDIA

Leading manufacturer of Special purpose machines (SPM) in Chennai, India. With our experienced and dedicated team, We have the capability to manufacture Advanced, complex special purpose machines for wide variety of purpose including high volume metal components production, automation of Feeder lines, automated spraying systems and many other machines to run critical and regular operations.

Special Purpose Machines offer tremendous value in terms of production of high volume parts / components at low investment and lower production cost compared with off the shelf machines. High productivity SPMs with custom designed tooling and fixtures are deployed for large volume component day in and day out.

With the deployment of limit switches, sensors, logic controls, automatic job clamping, remote / live monitoring, robot capabilities, SPM makes the best choice for high volume production parts.

Automated Spraying System

>>Automated Production Line

>>Assembly & Testing

>>Robotic Handling

>>Robotic Clipping

>>Rotary Indexing Table

>>Laser Integration (Welding, Laser Marking, Laser Cutting)

>>Leak Testing

>>Flash Testing

>>Control Systems

>>Pick & Place

>>Manual Workstations

>>Automated Parts Handling & Orientating

>>Vision Inspection & Quality Control

>>Packaging & Processing

>>Welding & Cutting

Many more…

AUTOMATED PRODUCTION LINE

Automated Production Line

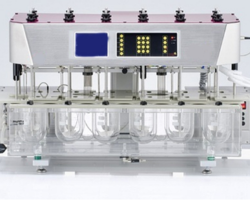

MICROPROCESSOR PERFORMANCE TEST MACHINES

We are extensive experience in implementing inspection& performance testing system. Often, a testing system requires electronic and mechanical functionality. This may include a part positioning system, rejection system, PLC – HMI – NI, optical sensing, vision system, scanning, pressure, leak, etc.

MACHINE SERVICE AND MAINTENANCE

We are highly acknowledged organization engaged in presenting remarkable range of Machine Maintenance. Today, Machine is the most important gadget in any modern day home. Given the huge Customer dependency on it and the need for better and efficient cleaning systems, many new technological discoveries and models keep hitting the market on a regular basis. Also, frequent overloading, voltage fluctuations, wear & tear, improper handling, electric shocks etc lead to the onset of many technical problems and compromise the efficiency and their proper functioning.

PERFORMANCE TEST RIGS

We are one of the leading organizations engaged in offering a wide range of Test Rigs. The rigs offered by us manufactured using in compliance with the international standards and norms. The rigs offered by us are designed using superior quality raw material and are widely demanded for their features like strong construction, low power consumption and durability. The technical know-how and expertise of our professionals have helped us in designing and developing a precision engineered gamut of Perfomance Test Rig. Under the strict supervision of these professionals, the complete range is specifically manufactured using premium grade raw material and components, procured from renowned vendors of the market.

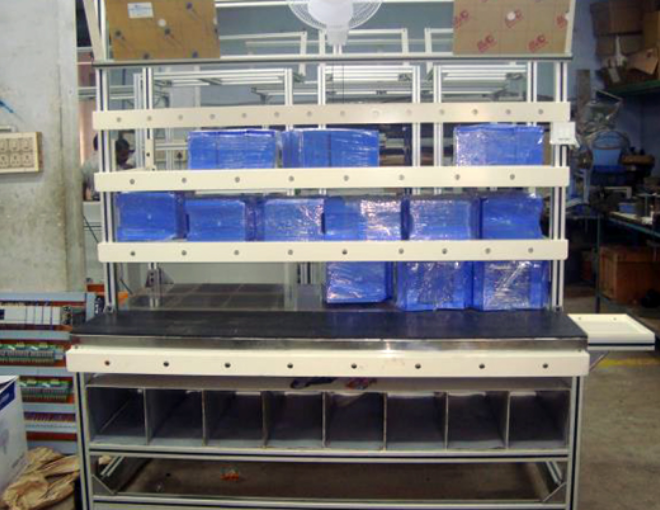

ALUMINIUM TABLES

We have gathered huge recognizance by developing highly demanded Aluminum Assembly Tables. Developed with a rust resistant aluminum framework the highly durable tables are capable to withstand rugged handling at industries. We are leveraging the skilled expertise of our team members who are crafting the quality compliant workshop tables that are verified for its resonance and durability. Further, the anti-corrosive tables are accessible from us in powder coated finish at a market leading price.

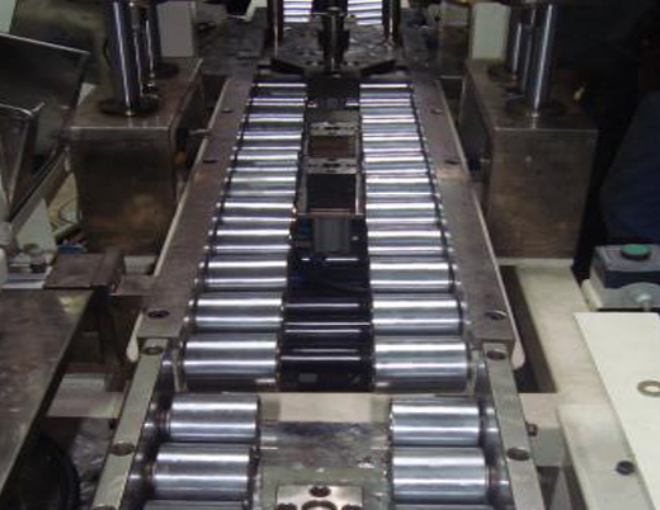

AUTOMATED ASSEMBLY LINE EQUIPMENT

We are one of the best manufacturers and suppliers of high speed Assembly Automation Equipment. Our equipment suit as per the clients requirement. This product is manufactured by experienced professionals using advance tools and quality proven material. Our product range is known for its long service life.

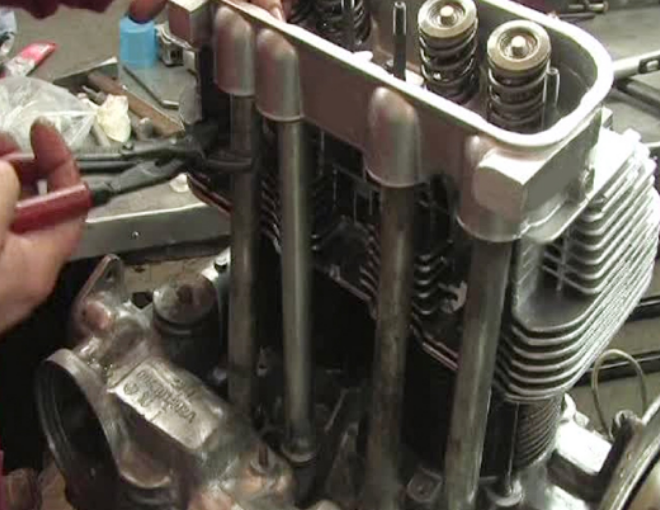

WET AND DRY LEAK TEST MACHINES

Wet Leak Testing machine detects leaks in components by dipping the component in water.This machine have an advantage over dry type is that it locates the leak on component.Components are like Engine Blocks, Engine Heads, Cover Cylinders, Shock Absorbers, Engine Valves, Gear Boxes, Power Steering, Oil Filters, Oil Pans, Manifold, Crank Cases, Fuel Parts, Mufflers, Batteries, Cooling Systems, electrical Parts, Brake Parts, Boosters, Air-conditioning parts, Engine Assembly, Cast Products and Non-Automotive products like Cans, Tins

MACHINING FIXTURE

With firm commitment to quality, we are betrothed in providing a superior quality assortment of Machining Fixture. The provided products are manufactured and designed under the strict supervision of our adroit professionals by using optimum quality raw materials and superior technologies. We provide these fixtures to the clients in diverse specifications and also in customized options to cater their needs and demands

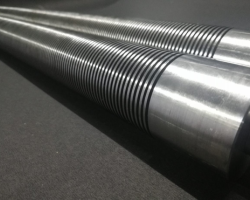

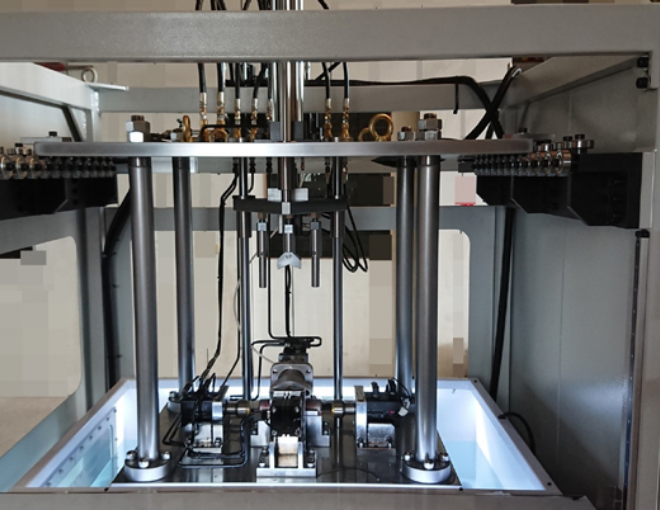

SPECIAL PURPOSE MACHINES

We build SPM Machines with latest technology available – Mechanical as well as Electronics. We use AC Servo Motors and Drives for best positioning and repeatability. Mechanical parts used are of high accuracy. SPM Developed – 5 Axis Drilling – Plastic Industry / Spiral Milling- Oil Field industry / Neck Milling for Gas Cylinders / Multispindle Gun Drilling – Pallet Die mfg. etc.

CONVEYOR SYSTEM

We offer our clients with a qualitative range of Conveyor System Equipment. This system is the solution to all types of material handling requirements of different industries. Our range is very cost effective, easy to maintain and saves considerable floor space. These are ideally suited to carry out efficient loading and thus, find usage in drying operations, painting, wet or oily applications and extreme temperature applications. We make use of high tech tools and machinery to engineer these products. Available at market competitive prices, these are highly demanded in the industry.

HEATER MACHINE

We provide superior quality range of Induction Billet Heater Machine in perfect design and standard size for high performance and reliability. Our products are manufactured using optimum grade materials and are used on large market scale. We ensure quality tested products which are secure, sustainable, well tested, verified and are largely supplied at competitive market range.

AIR CLEANING MACHINE

The machine works on principle of back pressure of Bottle which will be fed by the Turn Table to the conveyor where one star plate is given which is operated mechanically has given clutch for prevent the damage. Function of the star plate to push the bottle into inverter, There are three zone first is inverter which reverse the bottle second is cleaning section where the air pressure is to be supplied vacuum section is to be given where the dust is to be collect in a vacuum section , vacuum section is to be attached with dust extractor. Which extract the dust after this process bottle is to be entered into third zone (inverter) which converts the bottle into real Position for the next operation.